-

Information Extrusion Welding

-

Functionality

The welding rod gets via the rod feeder into the extruder body, is granulated, melted within the melting chamber, compressed and then transportet by the extruder screw to the outlet surface of the welding shoe. The preheating blower heats up the surface of the joining area on the base material (2 areas which are to be welded together). The preheating nozzle defines the width of the preheating area. The melt exits the welding shoe and is given the desired shape by it. The melt and the base material cool down together and the welding gets its final form and strength.

-

Information Wedge Welding

-

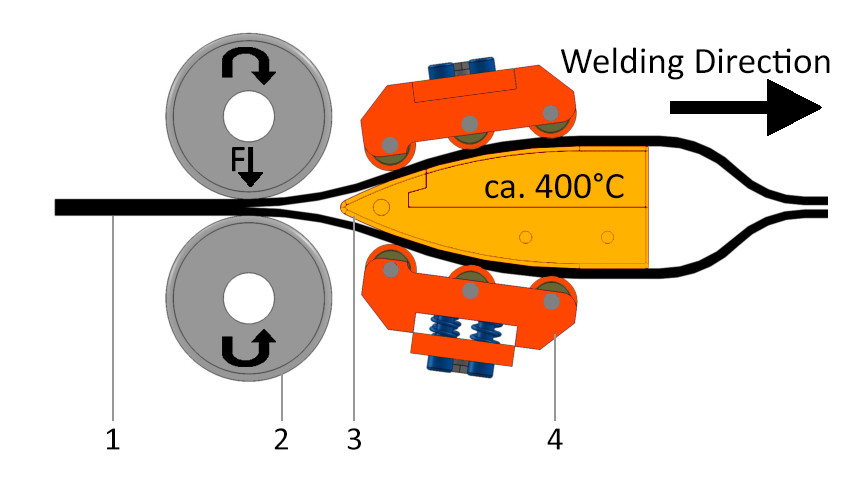

Functionality

The geomembranes are pressed onto the hot wedge by the pressure rolls. The hot wedge melts the surface of the geomembranes. The actuator rolls press the melted geomembranes with high force onto each other. The geomembranes cool down and solidify.